Expertise

What we do

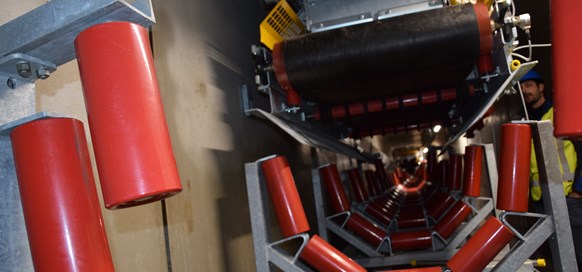

Around 25 million tonnes of sand will be moved from the Geertjesgolf to Deest on the Waal via a closed conveyor belt by 2032. Huisman Etech Experts and Moors Bergharen developed the system as a sustainable alternative to truck transport. The conveyor system is also a first in the sand mining sector. This incredible project combined all the disciplines Huisman Etech Experts has to offer.

Rob tells you more.

Geertjesgolf is one of the largest sand mining sites in the Netherlands. The client, Nederzand, wanted a sustainable way to transport the sand to the port in Deest. The solution was a two-kilometre-long closed conveyor belt built under the main road, saving 60 truck trips per hour. The conveyor belt is fully electric, low-noise and emits no harmful emissions. Huisman Etech Experts designed, manufactured and installed the electrical installation and control system for this unique conveyor belt.

Two sand dredgers are used for sand extraction. After the sand has been dewatered and sieved, it is transported to a 15-metre-high installation by conveyor belt. Two traverse wagons drive over it and deposit the sand at the sand depot. Two tunnels with conveyor belts run through the depot. Remote-controlled valves ensure that the correct selection of sand is delivered to the pipe belt conveyors.

Huisman Etech Experts engineered and implemented the electrical and control technology of the separation plant, the sand depot and the conveyor belt in-house. We installed three transformers to power the three plants with a combined 6,500 kVA. As a certified Siemens partner, we applied sustainable and high-quality Siemens technology. All installations are designed with sustainability and efficiency in mind.

In addition to supplying the electrical installations and control systems, we were also involved in the floating separation systems, using our extensive experience in the shipbuilding sector. This project combined all our disciplines, leading to a wonderful result. We also provide service and maintenance for the supplied installations. Because Geertjesgolf is only three kilometres from our Druten location as the crow flies, our field engineers can quickly be on-site in case of breakdowns, ensuring that the plants will run continuously for years to come.